SPIROGYRE

The Spirogyre sweep auger is designed to extract remaining products (like wheat, maize, barley, seeds, etc.) that free-flow with gravity but that can build up in flat bottom silos. The auger is activated once the gravity unload has been completed, ending the process with a 360° rotation inside the silo. The fully automatic design of the Spirogyre provides a safe and reliable solution that requires no human intervention.

Three types of Spirogyre:

S type

The electric motor is inside the silo, directly coupled to a reducer driving the auger.

Advantages: Simple and efficient, taking up little space. Certification: ATEX II 2D 125°C.

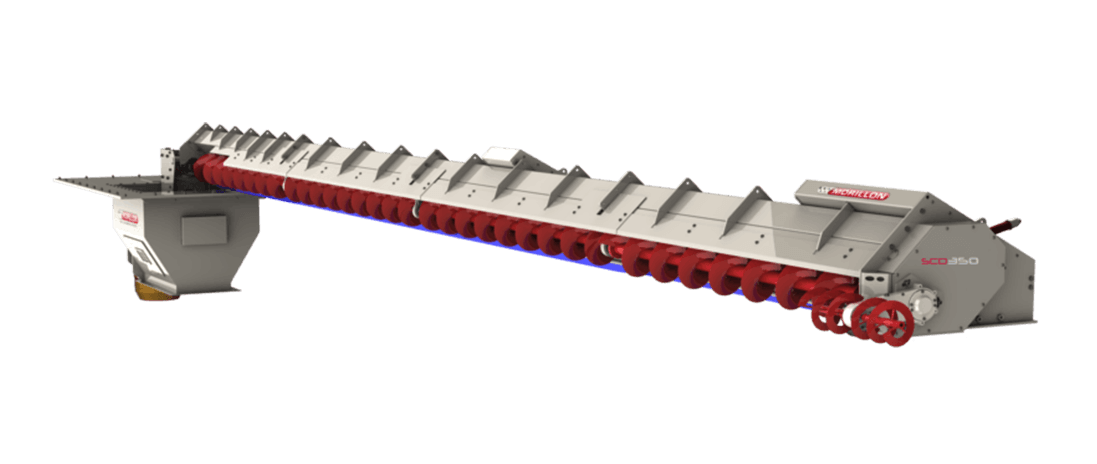

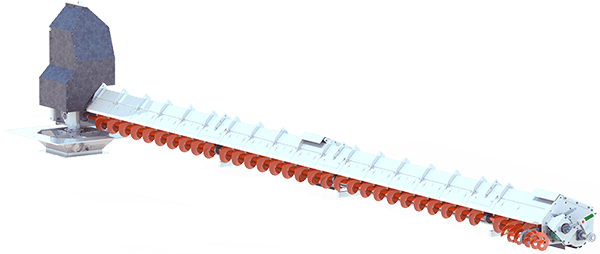

SCD type

The motor is under the silo, the transmission is provided by a V-belt drive system in a closed casing.

Advantages: Heavy-duty design, sturdy and easy to maintain, and allows for high-speed gravity flows. Certification: ATEX II 1/2D 125°C

Hydraulic Spirogyre

This version, which is the heir to Morillon’s expertise in the extraction of difficult products, combines the structure of a traditional Spirogyre auger with the hydraulic motorization used on our Hydraugyre unloaders for silos with diameters of 18 to 38 metres.

Advantages: Sturdy and takes up little space, with capacities up to 400 T/hr (based on wheat).

Spirogyre range:

- For silos between 6 and 38 metres in diameter, offering discharge capacities of 25 to 300 tonnes per hour, depending on the product.

Possible retrofit:

- To replace sweep augers, please contact us.

Options :

- Clearing screw

- Brushes

- Level detector

- Parked position detector